PLA Silk Dual Color Variety Pack (4x200g) - 1.75MM

PLA Silk Dual Color Variety Pack (4x200g) - 1.75MM

Sale price$29.99 USD

Regular price$34.99 USD

About PLA Silk Dual Color Variety Pack (4x200g) - 1.75MM

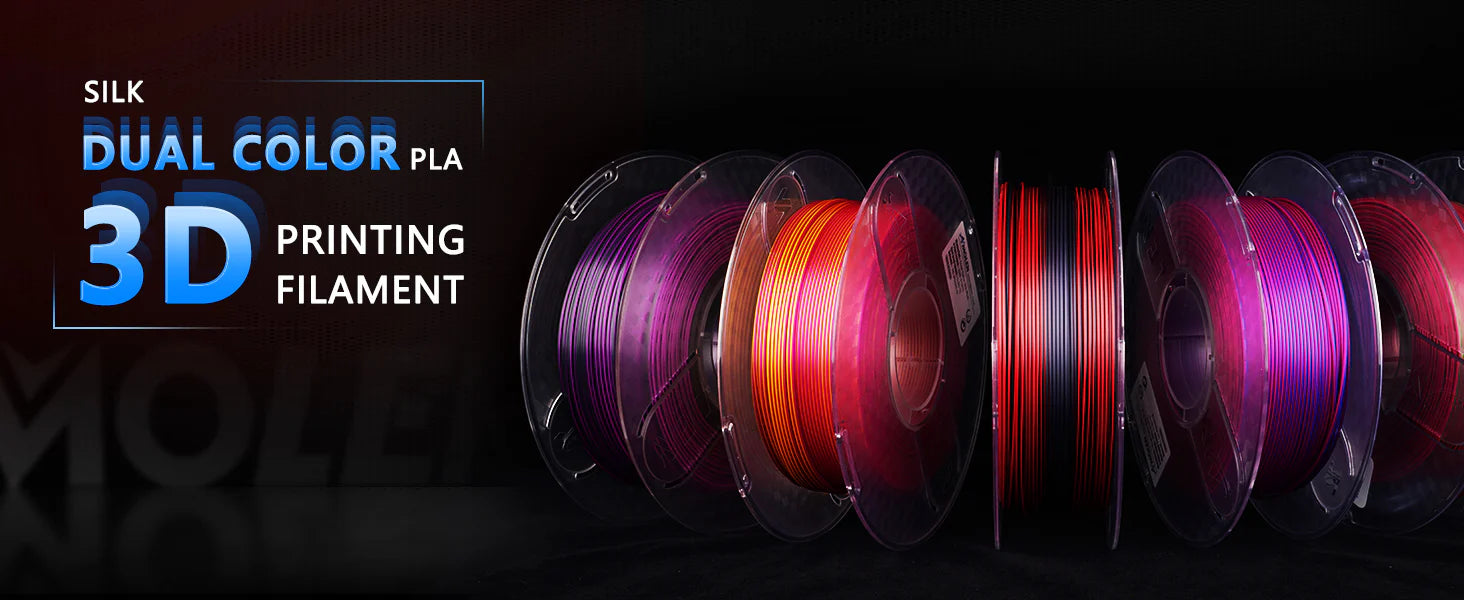

Dual-Color PLA for Vibrant and Artistic 3D Printing

Spool Net Weight

0.2 kg (200g)

Diameter

1.75mm

Tolerance

± 0.03mm

Print Temperature

200-220°C

Hot Bed Temperature

0-50 °C