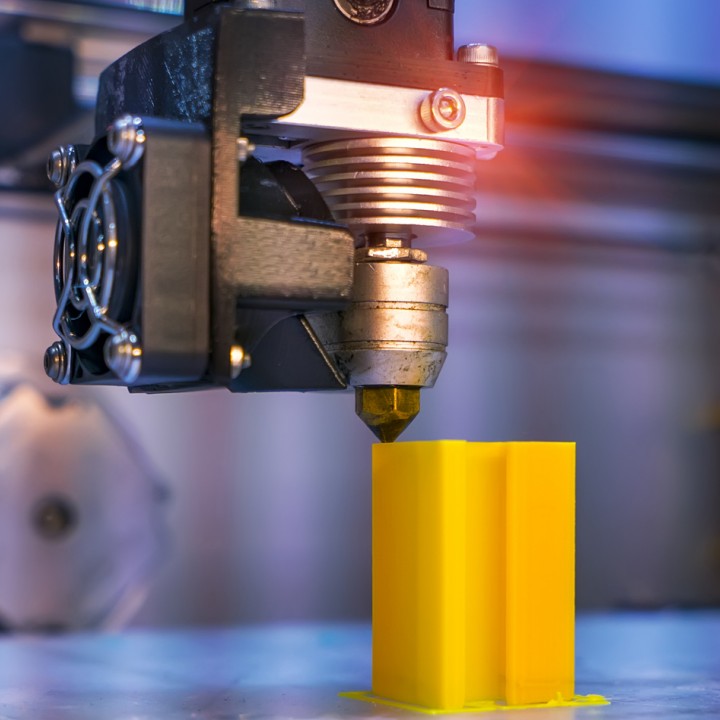

3D printing has revolutionized the way we create and manufacture products. One of the most important aspects of 3D printing is the ability to adjust the fill settings, which can greatly impact the strength and durability of the final product, as well as the amount of filament used. In this blog post, we’ll explore how to use 3D printing fill settings to enhance strength or save filament.

1. Understanding Fill Settings

Before we dive into how to adjust fill settings, it’s important to understand what fill settings are and how they impact the final product. Fill settings determine how much filament is used to create the internal structure of a 3D printed object. The pattern and density of the fill can greatly impact the strength and durability of the final product, as well as the amount of filament used.

2. Adjusting Fill Settings

To adjust fill settings, you will need to access the fill settings menu in your 3D printing software. Most software programs will have options for adjusting the fill pattern, density, and infill percentage. Here are some tips for adjusting these settings:

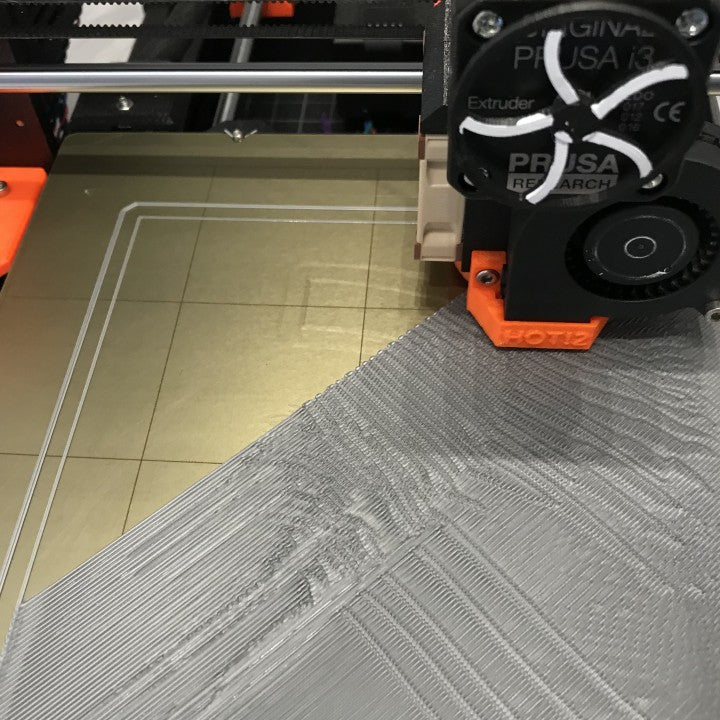

- Fill Pattern: The fill pattern determines the structure of the internal fill. Some common patterns include rectilinear, honeycomb, and concentric. Each pattern has its own strengths and weaknesses, so it’s important to choose the pattern that will best suit your needs.

- Fill Density: The fill density determines how much of the internal space is filled with filament. A higher density will result in a stronger, more durable object, but will also require more filament.

- Infill Percentage: The infill percentage determines how much of the object is filled with filament. A higher percentage will result in a stronger, more durable object, but will also require more filament.

3. Examples

Let’s take a look at some examples of how adjusting fill settings can impact the final product:

- A 3D printed phone case: A phone case that is used frequently may require a higher infill percentage and fill density to ensure durability and strength.

- A 3D printed vase: A vase that is purely decorative may require a lower infill percentage and fill density to save filament and reduce printing time.

Overall, adjusting fill settings is an important aspect of 3D printing that can greatly impact the strength and durability of the final product, as well as the amount of filament used. By understanding fill settings and how to adjust them, you can create 3D printed objects that meet your specific needs and requirements.